KNOWING FOR EXCELLENCE

Two decades ago we founded the TIDAL Audio GmbH and became worldwide famous for making maybe the finest audio systems under this sky – being said in countless references from the audio press worldwide: TIDAL.

We do know TIDAL is and always will be for most music lovers financially inaccessible, given the second to none uncompromised approach behind it. But with proven consistent excellence we now go the next step. And make things more possible for a wider audience without compromising the ideals we believe into: VIMBERG™.

Clients for real high end products want and need proven consistency of quality, a real heritage DNA and a waterproof story of “behind the curtain”. VIMBERG™ is not some start-up, but being designed and made from the same people making the TIDAL ultra highend masterpieces. And by that we mean: the same people with the same engineering skills, the same “we care” attitude and all is being designed and built under the same roof.

Imagine with me for a moment. Let’s say Bugatti decided that it wanted to build a car that sold for $29,000 USD, and this car would also look, smell, feel, and drive like a $215,000 USD Bugatti. Albeit some minor engineering and production compromises would have to be made, but overall — the experience and emotions it would produce would be almost identical. That is what TIDAL Audio founder Jörn Janczak has just done with the development of his new VIMBERG™ company. (Eric Shook, Audiohead.com)

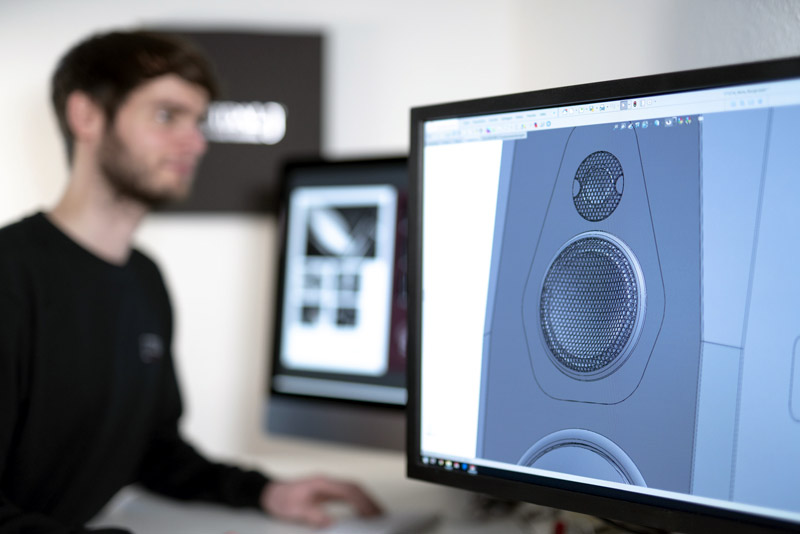

VIMBERG™ speakers are praised as incredible good looking. But all beauty is meaningless if it bases on an empty shell. VIMBERG™ speakers provide state of the art engineering and construction and are designed and engineered to perfection – aside of marketing fairy tales. There is only one way to prove excellence of speaker engineering: measurements! Why is that? Easy: flaws in the construction, such as resonances of the cabinet, a bad implementation of the drivers and impedance drops which give amplifiers a hard life, just to name here a few, can be measured – and therefore detected and shall be avoided. Simply, because sooner or later the ear will detect it and the user addresses that with flaws in sound.

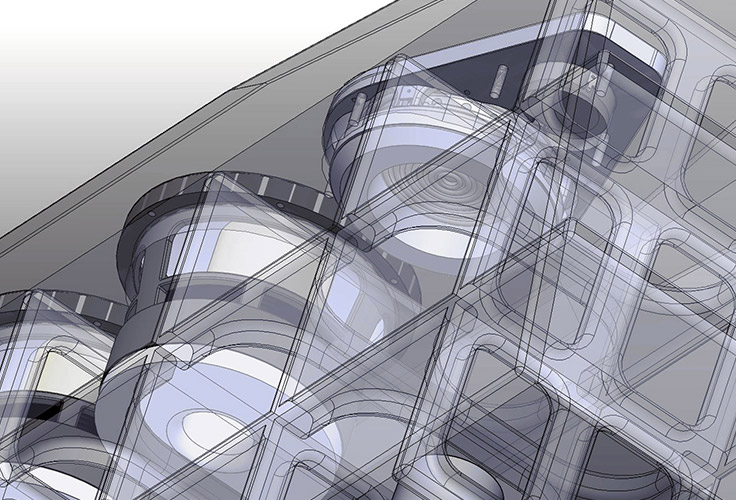

The construction is the most essential basic for all what follows after that. For example any kind of part quality is close to meaningless if it bases on a compromised design. VIMBERG™ is using some of the most advanced software to support the design of each speaker, for example the extensively braced low-noise cabinets or the complicated crossover designs. From the outside observed all speakers being a cabinet equipped with drivers seem to be often similar in construction, the truth is the inside makes a difference of night and day, since therein lays the DNA of every speaker. The DNA of how much the brand takes care and what it can do, and the DNA how satisfied and happy the owner will be later.

Each VIMBERG™ went thru the process of choosing the best materials for it. The VIMBERG™ cabinets are made out of waterproof fibreboard material, compressed after a blow-line-resin coating and are covered with spectacular glossy polyester real piano lacquer to seal it – and as side product let it appear extremely noble. The drivers do use diaphragms made out of aluminum sandwich, ceramic and diamond from the noble driver supplier Accuton. The crossovers do use for e.g. exclusively foil capacitors, air core inductors and come all from the noble suppliers Duelund and Mundorf. Not enough, all metal parts are being milled out of a complete block aluminum and do underline our approach.